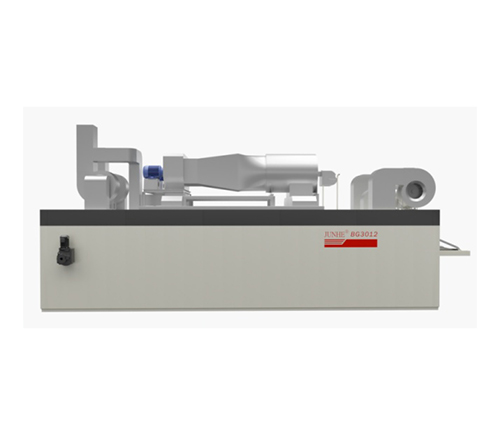

Profil produk

JUNHE®stepping tray-jinis ngobati tungku bisa nyukupi syarat lapisan saka fasteners otomotif lan bagean hardware, kontrol kumpulan, konsumsi energi kurang, safety lan lingkungan loropaken, nyegah bahan campuran, biaya operasi kurang, informasi, cerdas lan upgrade IOT.

FungsionalProperti

1,Standardisasi modul: kinerja stabil, modular, desain standar, kabèh mesin Déwan, plug and play, instalasi gampang, pilihan cerdas, upgrade gampang, cocog karo Junhe mesin nutupi standar.

2.Cilikpendhudhukan tanah: peralatan kompak, multilayer terpadu struktur stereoscopic, saklawasé rong pertiga kurang area saka tungku ngruwat conventional.

3.Ngirit energi banget lan ramah lingkungan: Recovery energi cooling, desain terlampir integral, koleksi terpusat saka exhaust online.

4.Manajemen batch apik: stepping tray jinis terus-terusan pra-panas lan ngruwat, saben tray cocog karo saben basket saka mesin lapisan, kontrol data kumpulan, nyegah bagean nyawiji, manajemen kumpulan apik.

5.Biaya operasi sing murah: Pre-heating, curing and cooling energy complementary control, energy saving, saving more than 20 % than conventional curing furnace, one side loading and unloading, ngurangi investasi cerdas lan biaya tenaga kerja.

Parameter teknis

| Kapasitas muat maksimal: | 200kg / tray | Ukuran tray: | 1200 × 1150 mm |

| Suhu tungku | 80 ~ 360 ℃, luwes | Metode pemanasan | Pemanasan gas, pemanasan listrik, opsional |

| Konsumsi energi gas alam | <25m³/jam | Total tray / kapasitas | 30 nampan, kapasitas maksimal siji jas: 6000kg / jam |

| Total daya | ≤35kw | Jinis transmisi | 2-4min / tray, mlaku lan luwes |

| Keseragaman suhu tungku area efektif | Bagean silang: ± 5 ℃ | Pre-heating / Curing wektu | 12 ~ 24 menit, 22 ~ 44 menit |

| Ukuran mesin | 12500 × 2750 × 4365 mm | Bahan kerja sing cocog | Auto parts mbutuhake kontrol kumpulan |

| Mesin lapisan sing cocog | JUNHE®DSP T500, JUNHE®seri DST-D800 | Cat sing cocog | Cocog kanggo kabeh jinis cat banyu-basa lan basa solvent |

* Parameter kinerja ing ndhuwur bisa beda-beda amarga proses manufaktur, pilihan listrik, instalasi

ukuran workpiece wangun lan proses pilihan.